Production Processes - Precision Engineered Components

LoneStar manufacture and supply a wide range of high quality precision engineered components to global OEMs and End Users across the Oil, Gas and Subsea industries.

Located in Leeds, UK - LoneStar Leeds is the Group's manufacturing facility specialising in the bespoke manufacture of products including valve gates, stems, seats and actuator components.

Operated by a team of skilled, experienced engineers LoneStar Leeds employs the very latest manufacturing technology to provide the highest levels of quality, precision and efficiency.

CNC Milling

|

- 13 no CNC machining centres

- 2300mm x 800mm maximum capacity

- Components up to 1000kg

- Vertical, horizontal and twin pallet machines

|

CNC Turning

|

- 13 no CNC machining centres

- 2300mm x 800mm maximum capacity

- Components up to 1000kg

- Vertical, horizontal and twin pallet machines

|

Spark Wire Eroding

|

- Complex, contoured shapes easily produced

- Allows machining of exotic materials such as super alloys, tungsten carbide, titanium etc

- Dimensional consistency throughout batches

- Elimination of heat distortion allowing hardened components to be machined

|

Surface Grinding

|

- Surface grinding generates the super finish necessary prior to lapping or carbide coating

- Cylindrical grinding provides not only the required finish on components manufactured from most base metals but also on components before and after hard chrome plating

- Rotary grinding ensures highly efficient stock removal

|

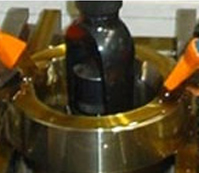

Honing

|

- A cost-effective precision honing service

- State of the art machine technology

- Faster production turnaround supplying components COMPLETE removal.

|

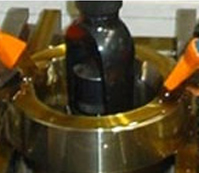

Lapping

|

- Stock removal controlled to within a few microns

- Flatness to 1 light band

- Surface finishes, using either conventional abrasives or diamond super abrasives, to obtain leak-proof mating without gasketing

|