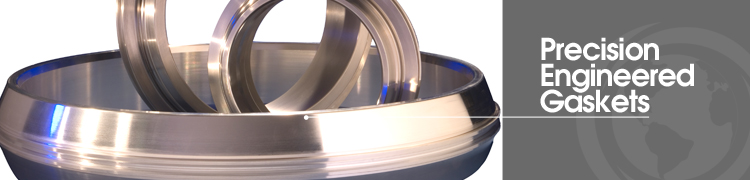

Precision Engineered Gaskets - critical components for subsea and surface applications

Precision engineered gaskets and seals are critical components used in both subsea and surface applications. Predominately, these parts are manufactured from all types of steels, stainless steels and high nickel alloys and are manufactured to very strict tolerances. LoneStar manufactures your precision gasket requirements on CNC machine tools in the US, UK and India. Currently, we operate over 20 different machine tools, ranging from small diameter bar-fed machines to large horizontal CNC lathes.

It is imperative that proprietary parts are manufactured to the customer's specifications. A deep understanding of your requirements is paramount to the successful delivery of a part 'on time' and defect free.

The list of gaskets and seals that can be precision engineered is endless and we can engineer parts to your request in a huge range of gasket types and materials. Below you will find a list of the most requested gaskets:

SBX

Ring type joints SBX are used on subsea assembly with flanges API 6BX, API 17SS and API 17SV. They can seal up to 5,000 PSI, according to API 17D for 17SS flanges and up to 10,000 PSI, according to API 17D for 17SV flanges.

SRX

Ring type joints SRX are used on subsea assembly with flanges API 17D - offshore, type 17SS and 17SV. They can seal up to 5,000 PSI, according to API 17D for 17SS flanges.

AX

Ring type joints AX are used in H4 hydraulic connectors - subsea production equipment such as BOP or underwater Christmas tree.

VX

Ring type joints VX are used in H4 hydraulic connectors - subsea production equipment such as BOP or underwater Christmas tree.

VX-HP (High Pressure)

Ring type joints VX are used in H4 hydraulic connectors - subsea production equipment such as BOP or underwater Christmas tree. Manufactured to perform under deep water of up to 4,000 meters (13,000 feet) depth.